TOOL SIZES

Hi-Res MFL(Ctool,TR4,Quantum and MaxTool) 6” to 42”

DEFORMATION: 6” to 42”

CALIPER: 6” to 48”

INS (INERTIAL MAPPING) 6” to 48”

COMBO (DEF + INS) 6” to 42”

COMBO (MFL + DEF) 6” to 42”

COMBO (MFL+DEF+INS) 8” to 42”

Hi-Res MFL(Ctool,TR4,Quantum and MaxTool) 6” to 42”

DEFORMATION: 6” to 42”

CALIPER: 6” to 48”

INS (INERTIAL MAPPING) 6” to 48”

COMBO (DEF + INS) 6” to 42”

COMBO (MFL + DEF) 6” to 42”

COMBO (MFL+DEF+INS) 8” to 42”

LINALOG MFL tool possesses the following features;

* Pipeline sizes: 6”to 42”

* High Resolution data 0.1” (2.5 mm) sampling for full coverage

* 3D pipeline mapping with INS for exact pipeline location

* 1.5D bends

* Reliable in critical environments (high pressure up to 3250psi)

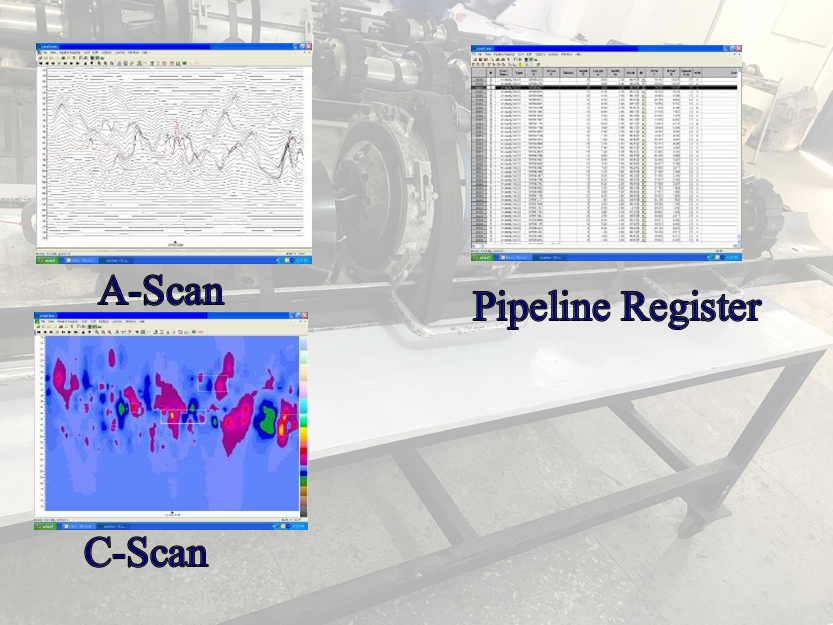

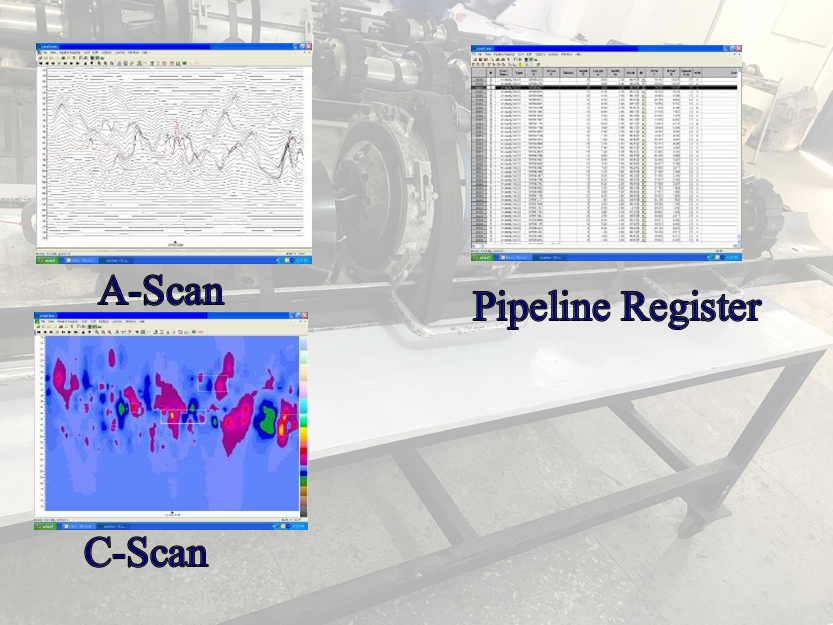

* Data visualization software

* Pile wall thickness (6mm – 25mm)

* Up to 400 Km in a single run

LINALOG DEF tool possesses the following features;

* Available from 6”to 42”

* High Resolution data 0.1” (2.5 mm) sampling for full coverage

* Max Operating Pressure (137-220)bar

* Designed for 1.5D bend

* Good data detection range up to 5.5 m/s

* Minimum sizeable depth 0.1”(2.5mm)

* Multi Channels (Deformation and IDOD)

* Up to 400 Km in a single run

Other Information on MFL;

* Technology originated by Tuboscope

* First ever Corrosion Inspection Technology; debuted in the 60’s!

* Continually Improved and Re-invented over the years

* Can Combo: MFL + INS + DEF